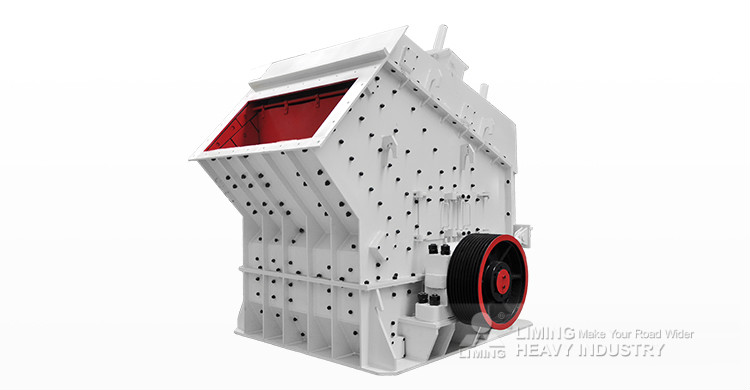

Impact Crusher  Chat Online

Chat Online

Capacity: 50-250TPH

Capacity: 50-250TPH

Impact Crusher is usually used as secondary crusher in the production line. It can crush many kinds of materials with max feed size less than 500mm and crushing strength less than 360 MP. The most outstanding advantage of impact crusher is that its finished powder is in good, cubic shape, non-tensile and cranny.

What Impact Crusher Plant Can do ?

Limestone, granite, basalt, andesite, quartz, silica, volcanic rock, marble, river stone, gravel, pebble, dolomite, sandstone, pozzolana, mountain stone, ballast, feldspar, Iron ore, copper ore, gold ore, manganese ore, etc.

Impact Crusher

0-5mm sand

5-10mm aggregate

10-20mm stone

20-40mm stone

Widely Applications:

Crusher in mining, quarry, metallurgy, chemical, refractory material, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

Top 5 Advantages of Impact Crusher

Unique structure, Energy-efficient, low consumption.

Hammer is made of high chrome, liner board is made of wearable materials.

Specially designed tooth impact plate.

Final products is cubic, discharge opening is adjustable.

Make the crushing flow chart simple.

Technical Data of Impact Crusher

| Model | Size of rotor (mm) | Feed opening (mm) | Max. feed size (mm) | Capacity (t/h) | Power of Motor (kW) | Weight (t) | Overall Dimensions (mm) |

| PF1010 | Φ1040×1000 | 510×1040 | 200 | 50-90 | 75(100) | 12.5 | 2455×2090×2800 |

| PF1210 | Φ1260×1050 | 465×1155 | 250 | 70-130 | 110(150) | 16 | 2582×2052×2810 |

| PF1214 | Φ1260×1400 | 465×1485 | 300 | 90-180 | 132(175) | 18.5 | 2582×2410×2810 |

| PF1315 | Φ1280×1500 | 700×1540 | 300 | 120-250 | 200(270) | 21 | 2930×2765×3053 |

Successful Project Case

120tph granite stone crushing line in Zimbabwe

Equipment: PF1214 impact crusher, PE600×900 jaw crusher, 3YZS1860 vibrating screen

Processed material: granite

Capacity: 120t/h

Input Size: 300-400mm

Output Size: 0-40mm

Application: construction

0086-371-86162511

0086-371-86162511  info@limingco-group.com

info@limingco-group.com

0086-371-86162511

0086-371-86162511

info@limingco-group.com

info@limingco-group.com