Jaw Crusher  Chat Online

Chat Online

Capacity: 40-350TPH

Capacity: 40-350TPH

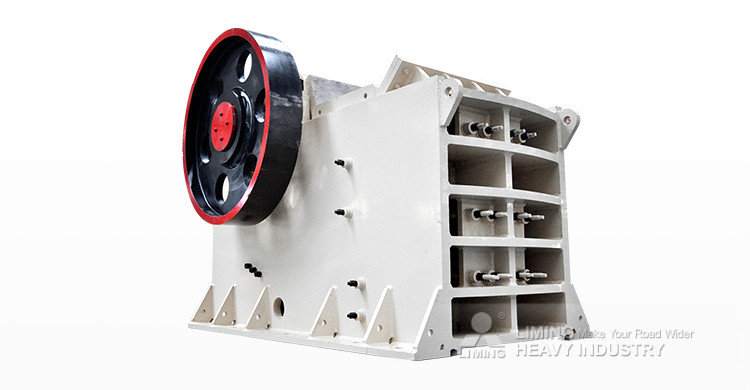

Jaw crushers are typically used as primary crushers, or as the first step process of stone crushing line. There are two types: coarse crushing and fine crushing, it will be the ideal equipment for primary crushing. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs.

What Jaw Crusher Plant Can do ?

Limestone, granite, basalt, andesite, quartz, silica, volcanic rock, marble, river stone, gravel, pebble, dolomite, sandstone, pozzolana, mountain stone, ballast, feldspar, Iron ore, copper ore, gold ore, manganese ore, etc.

Jaw Crusher

0-5mm sand

5-10mm aggregate

10-20mm stone

20-40mm stone

Widely Applications:

Crusher in mining, quarry, metallurgy, chemical, refractory material, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

Top 5 Advantages of Jaw Crusher

Focus on crushing hard stone as primary crusher.

High ratio of crushing, big capacity.

Simple structure, reliable working condition.

Easy maintenance.

Low operating cost.

Technical Data of Jaw Crusher

| Model | Capacity | Max Feeding Size |

|---|---|---|

| PE1200×1500 | 400~800t/h | 1020mm |

| PE1000×1200 | 315~550t/h | 850mm |

| PE900×1200 | 160~380t/h | 750mm |

| PE750×1060 | 110~250t/h | 630mm |

| PE600×900 | 60~130t/h | 500mm |

| PE500×750 | 50~100t/h | 425mm |

| PE250x1000 | 15~50t/h | 210mm |

Successful Project Case

75-100TPH Pebble Crushers for road construction in Salvador

Equipment: Jaw Crusher PE500X750, Cone Crusher CSB75, Sand Making Machine VSI7611, Vibrating Screen 3YZS1848

Processed material: pebble

Capacity: 70-100tph

Input Size: 500mm

Output Size: 0-5, 5-20, 20-40mm

Application: road construction

0086-371-86162511

0086-371-86162511  info@limingco-group.com

info@limingco-group.com

0086-371-86162511

0086-371-86162511

info@limingco-group.com

info@limingco-group.com