HST Single Cylinder Hydraulic Cone Crusher  Chat Online

Chat Online

Capacity: 70-2500TPH

Capacity: 70-2500TPH

HST series hydraulic cone crusher (Focus on hard stone) is a high efficiency cone crusher designed by introducing American technology and combining the metal nature on the world market. It applies to the primary and secondary crushing of mines and rocks, such as iron ore, gold ore, granite, limestone, quartzite ore, sandstone, pebble and so on. With full automatic control system, this machine can realize accurate regulation.

What HST Single Cylinder Hydraulic Cone Crusher Plant Can do ?

Limestone, granite, basalt, andesite, quartz, silica, volcanic rock, marble, river stone, gravel, pebble, dolomite, sandstone, pozzolana, mountain stone, ballast, feldspar, Iron ore, copper ore, gold ore, manganese ore, etc.

HST Single Cylinder Hydraulic Cone Crusher

0-5mm sand

5-10mm aggregate

10-20mm stone

20-40mm stone

Widely Applications:

Crusher in mining, quarry, metallurgy, chemical, refractory material, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy.

Top 5 Advantages of HST Single Cylinder Hydraulic Cone Crusher

High efficiency: The hydraulic cone crusher has support on both ends of the spindle, which is able to bear greater crushing force and greater stroke, coupled with the special shape of crushing chamber adapted to laminated principle, the machine has higher crushing efficiency.

Large production capacity: The hydraulic cone crusher has the perfect combination of design with crush stroke, crushing speed and crushing chamber shape, which make the machine's moving cone big end diameter in the same circumstances, the output is 35%-60% higher than the old spring cone crusher.

High quality aggregate: Adopts special crushing chamber and laminated crushing principle, resulting in inter-particle crushing effect, so that the finished product significantly increased the proportion of the cube, flake stone needles reduced and grain is more uniform.

Just replacing the fixed cone can achieve a variety of cavity shapes for fine crushing.

Easy maintenance: The structure of cone crusher is simple and compact. It has the features of stable performance, not easy to fault and convenient maintenance.

Technical Data of HST Single Cylinder Hydraulic Cone Crusher

| Model | Cavity | Maximum feed size(mm) | CSS min-max(mm) | Capacity(tph) | Power KW(HP) | Dimension (L×W×H) (mm) | Weight (t) |

| HST100 | S1(Extra Coarse) | 240 | 22-38 | 85-170 | 90(125) | 1535×1275×2710 | 9.6 |

| S2(Medium Coarse) | 200 | 19-32 | 70-130 | ||||

| HST160 | S1(Extra Coarse) | 360 | 25-54 | 120-345 | 132(175) | 2045×1635×3040 | 15.5 |

| S2(Medium Coarse) | 300 | 22-48 | 105-305 | ||||

| S3(Coarse) | 235 | 19-48 | 90-275 | ||||

| HST250 | S1(Extra Coarse) | 450 | 35-54 | 255-605 | 220(300) | 2675×2550×3940 | 28 |

| S2(Medium Coarse) | 400 | 29-51 | 215-515 | ||||

| S3(Coarse) | 300 | 25-51 | 190-490 | ||||

| HST315 | S1(Extra Coarse) | 560 | 41-76 | 335-1050 | 315(400) | 3110×2945×4480 | 43.5 |

| S2(Medium Coarse) | 500 | 38-70 | 305-895 | ||||

| Model | Cavity | Maximum feed size(mm) | CSS min-max(mm) | Capacity(tph) | Power KW(HP) | Dimension (L×W×H) (mm) | Weight (t) |

| HST100 | H1(Fine) | 135 | 10-32 | 45-130 | 90(125) | 1540×1280×2300 | 7.5 |

| H2(Medium Fine) | 65 | 8-19 | 35-80 | ||||

| H3(Extra Fine) | 38 | 4-16 | 27-60 | ||||

| HST160 | H1(Fine) | 185 | 13-38 | 66-210 | 132(175) | 2000×1550×2600 | 10 |

| H2(Medium Fine) | 90 | 10-32 | 65-165 | ||||

| H3(Extra Fine) | 50 | 6-25 | 48-105 | ||||

| HST250 | H1(Fine) | 215 | 16-44 | 110-395 | 220(300) | 2315×1830×2940 | 19.5 |

| H2(Medium Fine) | 110 | 13-38 | 115-340 | ||||

| H3(Extra Fine) | 70 | 8-32 | 90-255 | ||||

| HST315 | H1(Fine) | 275 | 16-51 | 170-665 | 315(400) | 2740×2200×3590 | 28.5 |

| H2(Medium Fine) | 135 | 16-38 | 190-505 | ||||

| H3(Extra Fine) | 65 | 13-22 | 205-320 | ||||

| HST560 | H1(Fine) | 300 | 22-70 | 448-1331 | 560(750) | 3300×2600×4463 | 51 |

| H2(Medium Fine) | 155 | 19-70 | 400-1098 | ||||

| H3(Extra Fine) | 80 | 10-44 | 280-669 | ||||

| HST750 | H1(Fine) | 370 | 25-70 | 480-2500 | 630(850) | 3800×3100×5305 | 80 |

| H2(Medium Fine) | 195 | 22-70 | 552-1115 | ||||

| H3(Extra Fine) | 80 | 10-51 | 364-790 |

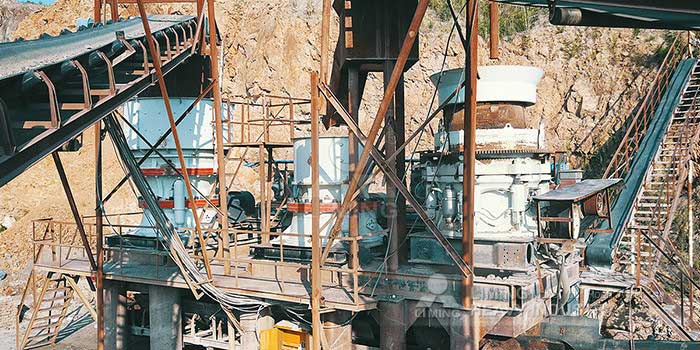

Successful Project Case

250tph river stone crushing line in Philippines

Equipment: HST160/H1 cone crusher, PE750x1060 jaw crusher, 2 sets of XL915 sand washing machine, 4YZS1848 and 4YZS1860 vibrating screen

Processed material: river stone

Capacity: 250tph

Input Size: 0-700mm

Output Size: 0-6.35mm, 6.35-19.05mm, 19.05-25.4mm, 25.4-50.8mm (0"-1/4", 1/4"-3/4", 3/4"-1", 1"-2")

Application: building aggregate

0086-371-86162511

0086-371-86162511  info@limingco-group.com

info@limingco-group.com

0086-371-86162511

0086-371-86162511

info@limingco-group.com

info@limingco-group.com